Tobacco:

Electronic Edition.

Virginia-Carolina Chemical Corp. Crop Book Dept.

Funding from the Institute for Museum and Library Services

supported the electronic publication of this title.

Text transcribed by

Apex Data Services, Inc.

Images scanned by

Melissa Meeks

Text encoded by

Apex Data Services, Inc., Andrew Leiter, and Jill Kuhn Sexton

First edition, 2002

ca. 150 K

Academic Affairs Library, UNC-CH

University of North Carolina at Chapel Hill,

2002.

Source Description:

(title page) Tobacco

Virginia-Carolina Chemical Co. Crop Book Dept.

50 p.

Richmond, Virginia

Published by Virginia-Carolina Chemical Co.

1915

Call number Cp633.71 V81t (North Carolina Collection, University of North Carolina at Chapel Hill)

The electronic edition is a part of the UNC-CH

digitization project, Documenting the American South.

The text has been entered using double-keying and verified against the original.

The text has been encoded using the

recommendations for Level 4 of the TEI in Libraries Guidelines.

Original grammar, punctuation, and spelling have been preserved. Encountered

typographical errors have been preserved, and appear in red type.

Any hyphens occurring in line breaks have been

removed, and the trailing part of a word has been joined to

the preceding line.

All quotation marks, em dashes and ampersand have been transcribed as

entity references.

All double right and left quotation marks are encoded as " and "

respectively.

All single right and left quotation marks are encoded as ' and ' respectively.

All em dashes are encoded as --

Indentation in lines has not been preserved.

Running titles have not been preserved.

Spell-check and verification made against printed text using Author/Editor (SoftQuad) and Microsoft Word spell check programs.

Library of Congress Subject Headings,

Languages Used:

- English

LC Subject Headings:

- Tobacco -- Fertilizers.

- Tobacco curing.

- Tobacco -- Harvesting.

- Tobacco industry -- North Carolina.

- Advertising -- Tobacco.

Revision History:

- 2002-10-07,

Celine Noel and Wanda Gunther

revised TEIHeader and created catalog record for the electronic edition.

-

2002-01-31,

Jill Kuhn Sexton

finished TEI-conformant encoding and final proofing.

-

2001-10-26,

Andrew Leiter

finished TEI/SGML encoding

- 2001-09-26,

Apex Data Services, Inc.

finished transcribing the text.

[Cover Image]

Page ad1

(From Southern Ruralist, Atlanta, Ga.)

A Great Product

Real Prosperity Maker

ONE of the greatest institutions of the United States is the company that manufactures V-C Fertilizers, which was established more than 20 years ago. It operates about 50 Fertilizer Factories throughout the Eastern half of the United States, with sales offices at centrally located points.

The Fertilizer Factories of this company are the most extensive and complete in the world, their equipment consisting of the most modern mechanical devices ever invented. These plants are all located at points where economical shipping conditions exist, both by rail and water, and occupy thousands of acres of ground, employing about 10,000 persons in the manufacture of complete High Grade Fertilizers.

The Company operates an extensive chemical labratory, equipped with the most complete and perfect apparatus obtainable. Here daily tests and analyses are made of all V-C Fertilizers before shipped, thereby assuring the absolute reliability and perfection of V-C Fertilizers at all times. No other Fertilizers are more accurately and carefully analyzed and mixed than V-C Fertilizers are.

Beginning with but five factories in 1895, it is at once apparent why the company manufacturing V-C Fertilizers, has assumed such vast and important proportions in the Fertilizer Industry. Many of its Brands have been on the market for 50 years. Quality and Highest Grade have been the watchword of those responsible for the great consumption which V-C Fertilizers now enjoy.

A vast army of planters and farmers testify to the excellence of V-C Fertilizers, and it is a recognized fact to what extent the company is responsible for "Increased Yields per Acre."

Indeed the fields of the Great Eastern half of the United States have become famous through their prosperity, and the V-C Company has helped to make them so. Its aim is to make these vast fields still greater in their productiveness by hearty co-operation with the tillers of the soil.

* * * * * * * *

IMPORTANT: This book was written by a practical farmer who has made a life's study of how to get most out of Soils and Crops. To what extent V-C is a Crop Food and a Permanent Soil Builder is evidenced by the numerous testimonials received from thousands of successful farmers and planters who have applied V-C, a few of these will be found in this book.

WHY NOT V-C NOW?

[Title Page Image]

Tobacco

Published by

CROP BOOK DEPARTMENT

VIRGINIA

CAROLINA

V-C Fertilizers

CHEMICAL

CO.

ILLUSTRATIONS

FROM PHOTOGRAPHS OF V-C CROPS

AND

PHOTOS USED BY COURTESY OF

DOUBLEDAY, PAGE & CO., H. C. WHITE & CO.

UNDERWOOD & UNDERWOOD

V-C SALES OFFICES

- Richmond, Va.

-

Norfolk, Va.

-

Alexandria, Va.

-

Durham, N. C.

-

Winston-Salem, N. C.

-

Baltimore, Md.

-

Charleston, S. C.

-

Columbia, S. C.

-

Jacksonville, Fla.

-

Cincinnati, Ohio.

-

Shreveport, La.

-

New York City.

-

Atlanta, Ga.

-

Savannah, Ga.

-

Columbus, Ga.

-

Memphis, Tenn.

-

Montgomery, Ala.

V-C SALES OFFICES

Copyright 1915, Virginia-Carolina Chemical Co., Richmond. Va

Page 2

BRINGS HIM MORE MONEY THAN ANY OTHER

"As a producer of fine Tobacco, I do not feel that I can say enough for V-C Fertilizers. It makes me Tobacco that brings more money than any other Fertilizer I can get, and I have tried many other Brands but none equaled yours. I believe it to be the best thing on the market for Tobacco, and shall use it exclusively in the future. It has also given me fine results on Corn and Vegetables, which goes to prove that it is made of good material."

V. C. LOVE, Kenbridge, Va.

Page 3

INDEX

- Air Curing . . . . . 30

- Atmosphere . . . . . 34

- Beds, Care of . . . . . 19

- Bedding, Cost . . . . . 7

- Beds, Cloth Covered . . . . . 10

- Burley Tobacco . . . . . 44

- Color . . . . . 32

- Crop Uniformity . . . . . 12

- Cultivation . . . . . 21

- Curing . . . . . 33

- Curing, Burley . . . . . 35

- Curing, Cigar . . . . . 34

- Curing, Export . . . . . 37

- Curing, Perique . . . . . 38

- Curing, Shade Grown Wrapper . . . . . 35

- Curing, Sun-Cured . . . . . 35

- Curing, Yellow Tobacco . . . . . 36

- Distance to Plant . . . . . 20

- Export Tobacco Classifications . . . . . 44

- Fertilizing Beds . . . . . 9

- Fertilizer Tests in N. C. . . . . . 16

- Fertilizer Tests in Tenn. . . . . . 16

- Fertilizer Tests in Texas . . . . . 14

- Fertilizing Tobacco . . . . . 17

- Fire Cured . . . . . 44

- Free V-C Crop Book Coupon . . . . . 51

- Grades . . . . . 39

- Handling Cured Tobacco . . . . . 38

- Handling Export Tobacco . . . . . 40

- Handling Yellow Tobacco . . . . . 39

- Harvesting . . . . . 25

- Harvesting Burley . . . . . 30

- Harvesting Cigar . . . . . 28

- Harvesting Export . . . . . 32

- Harvesting Perique . . . . . 33

- Harvesting Shade Grown Wrap . . . . . 29

- Harvesting Sun-Cured . . . . . 30

- Harvesting Yellow Tobacco . . . . . 30

- Heat . . . . . 36

- Insects . . . . . 40

- Leaves 32

- List of Free V-C Crop Books . . . . . 50

- Machine Planting . . . . . 20

- Manure . . . . . 18

- Marketing Tobacco . . . . . 43

- Modern Tobacco Culture . . . . . 4

- Packing . . . . . 43

- Pests . . . . . 13

- Ripening . . . . . 28

- Seed Bed Management . . . . . 5

- Seed Plants . . . . . 24

- Selection . . . . . 24

- Setting the Plants . . . . . 19

- Shade Grown . . . . . 37

- Sheds . . . . . 34

- Soil Preparation . . . . . 12

- Sorting Burley . . . . . 39

- Sowing the Seed . . . . . 8

- Stable Manure . . . . . 18

- Stalks . . . . . 32

- Stems . . . . . 37

- Sterilizing Seed Beds . . . . . 6-7

- Stringing . . . . . 29

- Stripping . . . . . 35

- Stripping Burley . . . . . 39

- Suckering . . . . . 23

- Topping . . . . . 22

- Transplanting . . . . . 19

- Varieties . . . . . 43

- Weeds . . . . . 22

Page 4

Modern Tobacco Culture

A Crop Which Offers Great Reward: Profitable tobacco growing is both a science and an art and is controlled to a very great extent by the environment of the crop. Tobacco is a sensitive plant. Its yield, composition, physical characters and market value are each and all greatly influenced by soil, climate, weather, fertilization and the treatment given it by the grower from seed-selecting to market. When tobacco is placed on the market the price it brings also depends upon the skill and care exercised in its curing and fermenting. The successful production of tobacco of high grade requires technical knowledge of the requirements of the crop and of the things necessary for the development of the qualities which bring high prices. There is no important farm crop the value of which is so dependent upon the knowledge, care, skill, good judgment and experience of the grower. Of the various factors entering into the successful production of tobacco of superior qualities, no others are so important as the fertilization of the growing crop and the management of the curing process. The great variation in types of tobacco grown in the United States, the diversity of soil characters in the tobacco section, the necessity and effects of commercial Fertilizers, and the mysteries of curing all conspire to make successful tobacco culture a complex subject offering great reward to the grower who is a master of his business.

This is the kind of Tobacco grown when well fed with V-C Fertilizers. Tobacco grown on the farm of Mr. R. H. Rigsbee by Mr. W. R. Chamblee, Durham, N. C., using about 900 lbs. of V-C per acre.

Page 5

Seed Bed Management

First Essentials to Profitable Crop: Tobacco plants are transplanted to the field after having attained a desirable size in the seed-bed. The exposure of the seed-bed and its soil character and soil condition together with the fertilization and care given it control the quality of the young plants produced, and the quality of those plants to a great extent controls the value of the crop at harvest time. Plants of uniform size, with a compact and abundant supply of root and a healthy and vigorous top are among the first essentials to a profitable crop. The production of such plants depend upon the selection of a good location for the seed-bed and upon its preparation, fertilization and the protection of the plants from diseases and insects. A southern or eastern exposure with timber to the north and west will give the greatest amount of sunshine and protection from north and west cold winds. The bed should be thoroughly drained, protected from surface wash and nearly level. If such a place may be found in a forest the prospective tobacco grower is fortunate. The soil should be mellow, friable and well filled with humus. If possible to avoid it, do not select a place filled with new weeds unless ample facilities will be provided for most thoroughly burning or sterilizing the bed before sowing the seed. If a desirable spot in the woods cannot be found, old briar patches, hedge rows or fence rows or similar spots made loose and mellow by the long accumulation of humus will, if properly prepared, make good plant-beds.

A Virginia Tobacco Plant-bed. Should the Tobacco growers of any one of the many Tobacco sections of the United States be prohibited the use of Commercial Fertilizers, they would have to go out of business. Hence, one of the best Fertilizers you can buy has proven to be V-C.

Good Care and Attention Required: As our forests disappear it becomes more difficult to find desirable conditions for seed-beds and many growers continue to use the same bed year after year. This may be done to advantage if good care and attention are given the beds when they are not in use and judicious application of Fertilizers are made for each crop of plants. If the bed is to be used again all unused tobacco plants should be destroyed before they attract insects that prey upon them and before tobacco diseases have gotten a foothold. When no more plants are needed cultivate the bed thoroughly and

Page 6

destroy all growth. After this has been done cover the bed to a depth of five or ten inches with old straw, leaves, corn stalks or some similar material free from weed seeds. The covering should be dense enough to prevent all weed growth that might appear through the summer. Poles or brush should be placed upon this covering to hold it in place. Such a covering will suppress all weed growth, prevent surface washing, supply humans and keep the soil in a loose and mellow condition for the next year's crop of plants. Throughout the summer the beds should be visited occasionally and all weeds near them that might produce seeds be destroyed. Such a bed should not require burning if the cover material has become pretty well rotted by mid-winter.

If Best Results are Desired: It is necessary that commercial Fertilizers be used on all plant beds if best results are expected; and upon beds used two or more years in succession there should be made a liberal application of a high-grade Fertilizer, applied in the fall and repeated in the spring just before the seed are sown. Tobacco plants grown in a poor or dry soil require considerable length of time for them to reach the trans-planting size; they have to send out long, scattering roots, which delays the development of the above ground part of the plant, and when taken up for setting in the field an undue proportion of the roots are broken off, and the plants require considerable time for their recovery from the damage done and are slow to start growth in the field. In a well fertilized seed-bed the roots find all the food needed near at hand and make a compact growth and are easily taken up for transplanting. Liberal fertilization and an abundance of water are necessary to the production of such plants.

Another Tobacco Plant-bed. The plant food in a low grade Fertilizer eventually costs more than the plant food in a High Grade article and is not so good. Use the best which has proven to be V-C Fertilizers.

Sterilizing the Seed-Beds with Steam

A Most Practicable and Profitable Method: This was found by the Connecticut Experiment Station to be both practicable and profitable. The practice consists either in steaming the soil sufficiently to kill all the weed seeds and microbes in it to a depth of two inches or more, or in treating the beds with formalin for the same purpose in part. Beds sterilized by steam will need no weeding, as only an occasional weed

Page 7

will appear before the seeding plants are transferred to the field. This saving of labor alone will pay the cost of sterilizing when the equipment for sterilizing has been provided. Plants grown in sterilized beds are not only freer from diseases, but start quicker, grow faster and are better plants than those grown in unsterilized soil. The root rot and other fungus diseases appear to be completely destroyed by sterilization and are also to a great extent destroyed by the formalin treatment.

Requirements of the Steam Plant: A six or eight horse-power steam boiler maintaining a pressure of 75 to 100 pounds, a steam hose with connections which will stand such a pressure will answer. The sterilizing pan is made of 18-gauge galvanized iron, and has a handle at each end which is fitted with hose nipple. The pan is 6 × 10 feet square and six or eight inches deep. A tight wooden box of about the same dimensions is equally as effective and, since wood is a poor conductor of heat, such a box requires less heat than a metal box.

Cost Reduced 100%: After the bed has been prepared by raking smooth and fine, and fertilized and is ready for sowing the seed, the sterilizing pan is inverted over one and the edges pressed well into the soil of the bed so as to confine the steam. Between 75 and 100 pounds of steam is maintained for not less than half an hour or forty-five minutes. The pan is then moved to the next section of the bed and the steamed area covered with burlap or some similar material that the heat may be confined in the soil as long as possible. The Connecticut Experiment Station found that to sterilize 180 square yards of bed cost $6.00 and that no weeding was needed on the sterilized beds, while the weeding of 90 square yards of beds up to the time the young tobacco plants were removed cost $12.00. The plants on the unsterilized beds were a week later.

Sterilization with Formalin and Formaldehyde

Another Effective Method: This method was also found to be effective, though steam sterilization was more convenient when a boiler

"The average Tobacco grower does not use half as much Fertilizer as would be most profitable and often four times the amount commonly used per acre would give in return more than four times this profit from the use of the greater quantity."

Page 8

was available. For small beds and in the absence of equipment for applying steam the formalin treatment may be substituted. It is applied in the fall when the soil is dry. One part of forty per cent. formalin is added to 100 parts of water (one pint formalin to 12½ gallons of water) and this solution which is gradually sprinkled over the bed at the rate of 9 or 10 gallons to the square yard, taking care not to puddle the soil. The bed should be covered with canvas, burlap or sash to confine the fumes. If the formalin treatment is given in the spring, seeding should be delayed until a week after the treatment was applied.

900 lbs. of V-C Fertilizers per acre produced this excellent field of Tobacco grown on farm of Mr. R. H. Rigsbee, Durham, N. C., by Mr. W. R. Chamblee. Photo taken August 20th, 1915.

Sowing the Seed

First Class Plants Necessary to First Class Results: This is an operation in which skill and experience count for much in securing an even stand and strong plants. Assuming a well prepared plant-bed and good seed, too many seeds as a rule, are used. An ounce of tobacco seed contains about 300,000 seeds; and if only two out of three of these grow, an ounce is ample for 6 square yards or 864 square feet. This would give more than two plants to the square inch of plant-bed, if every seed should grow, and this is too thick for the production of the best plants. If the plants are too thick in the seed-bed their vitality

Page 9

will be weakened, they will become "long-legged" or "spindling" with poor roots. It is suggested that one once of good seed evenly sown over six square yards of bed will give the best results. After the bed has been gotten ready and a week or two before the seed are to be sown, apply one or two pounds of high-grade Fertilizers to every six square yards of bed and thoroughly chop and rake it into the soil so as to have it equally distributed through the first inch or two of surface soil. This Fertilizer should contain about 8 to 12 per cent. of phosphoric acid and potash and about half as much nitrogen. Strong, vigorous plants of uniform size are important elements of success in tobacco growing and liberal fertilization of the plant-beds will produce such plants. Indifferent attention to the plant-bed often results in poor plants. Every tobacco grower should realize that first class plants are necessary to first class results. Defective plants and plants irregular in size are responsible for irregular stands; lack of uniformity in size and quality of plants and for irregular ripening.

Even Distribution Important: It is highly desirable that the seeds germinate promptly so that all the young plants may start growing with an equal show. To insure this it is well to soak the seed in water for about two days. They are then dried and sown as suggested further on. To soak the seed, place them in a tumbler and add only enough water to float a few of the seeds. In about 30 to 40 hours the seeds will have absorbed about all of the water and their hard outer coats will have been softened. Tobacco seeds are so small that they cannot

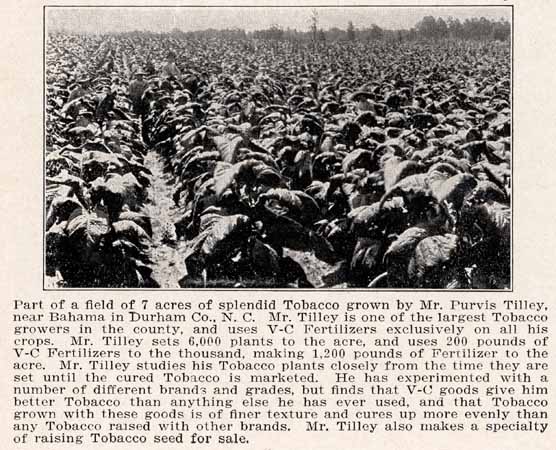

Part of a field of 7 acres of splendid Tobacco grown by Mr. Purvis Tilley, near Bahama in Durham Co., N. C. Mr. Tilley is one of the largest Tobacco growers in the county, and uses V-C Fertilizers exclusively on all his crops. Mr. Tilley sets 6,000 plants to the acre, and uses 200 pounds of V-C Fertilizers to the thousand, making 1,200 pounds of Fertilizer to the acre. Mr. Tilley studies his Tobacco plants closely from the time they are set until the cured Tobacco is marketed. He has experimented with a number of different brands and grades, but finds that V-C goods give him better Tobacco than anything else he has ever used, and that Tobacco grown with these goods is of finer texture and cures up more evenly than any Tobacco raised with other brands. Mr. Tilley also makes a specialty of raising Tobacco seed for sale.

Page 10

not be easily sown unless mixed with some other material. An even stand and uniformity in size of plants cannot be secured if the seeds are not evenly sown in the seed-bed. The material used for mixing with the seed should be very fine and contrast strongly with the color of the seed-bed that the sower may be guided in making an even sowing. Ordinary corn meal is a good material for this purpose and sifted ashes do nearly as well if they are of color that contrasts with the surface of the seed-bed. An ounce of seed should be mixed with about two gallons of meal or ashes, and the mixture divided into at least two equal parts, and each part separately sown as uniformly as possible over the entire bed. Dividing the seed thus will aid very much in securing an even distribution of seed and consequently an evenly distributed stand of plants.

A Simple and Sure Method: Tobacco seeds should not be covered, but merely pressed into the surface with the back of a spade; by tramping repeatedly over the bed with the feet; or by pressing them in with a plank upon which the operator stands, turning the plank over

"In the production of Tobacco of high price, heavy yields and of good quality, V-C Fertilizers exercise a most controlling influence." See last page for evidence of this.

and standing on it again. Boards 8 × 10 inches or 8 × 12 inches may be strapped to the feet and the seed pressed into the soil by the operator walking over the bed after the seed have been sown until the surface has been evenly pressed down. Probably the simplest and surest method is to sprinkle the bed with water as soon as the seed are sown. This, however, must be done with care and by no means too much water used. The water should be put on with a fine spray nozzle and at no time put down enough to allow the water to stand on the surface or run. This brings the seed in close contact with the moist earth and insures quick and uniform germination. The surface of the bed should never be allowed to become dry after the seed are sown, nor should it be made too wet. If too much water is used the seed will be floated into masses here and there, and the plants when they grow will be crowded in some places and too thin in other places. If the weather is bright and windy, water daily if necessary.

Cloth Covered Beds

Safe-Guarding the Plants: These are not only a protection against the attack of insects but to frost as well. The cloth covering conserves moisture and the young plants develop more rapidly and are more uniform in size. The beds are covered with cheese cloth or some similar

Page 11

material. Boards are placed about the beds and to these the cloth is nailed, stretching the cloth evenly and tight. Strips of cloth are sewed together in width to fit the bed. Wires are stretched across the bed so as to hold the cloth from the plants, the wires are five or six inches from the surface of the bed and at sufficient intervals apart to hold the cloth well from the plants. The cloth should be securely and tightly fastened so as to exclude all insects and maintain a uniform and higher temperature of the air above the plants. The cloth should be removed about ten days before transplanting begins, so that the

Three views on Mr. W. M. Hinson's Tobacco fields, Enfield, Conn., who used 3,000 lbs. of V-C Fertilizers per acre, reaping a bountiful crop of fine Tobacco. See article on Northern Grown Tobacco, page 46.

Page 12

A common sight where V-C Fertilizers have been applied. This bountiful field of Tobacco is evidence of the efficacy of V-C Fertilizers as a crop and soil builder.

plants may become accustomed to outside conditions. If the plants threaten to become too large before they are transplanted their growth may be checked by removing the cloth earlier. While in the bed spraying with arsenate of lead will effectively control all insects that attack the leaves, using from 4 to 5 pounds of the arsenate of lead to 50 gallons of water. While the plants are in the bed, watering the bed should continue whenever moisture is needed. The bed should never be allowed to become dry nor should it be made too wet, though it is preferable to water thoroughly at longer intervals than not to apply enough water and to water too frequently. The water should be applied late in the afternoon. Too much water in damp weather may cause serious damage to the young plants if the beds are not ventilated. Lack of ventilation and too much moisture present conditions favorable to the "damping off" and other funguous diseases. A slight raising of the plant-bed cover at both ends of the bed will often be a means of averting injury by thus removing surplus moisture. The disease known as "calico" is often started in a plant-bed by the use of tobacco-water made from tobacco stems. It is not advisable to use such water unless it has been thoroughly boiled for several hours and this is too expensive for the good it does.

This excellent Tobacco was grown on the farm of Mr. John W. Lamberts, Germantown, N. C., who used V-C Fertilizers to be assured of a fine crop and an increased yield.

Page 13

Preparation of the Soil

Necessary to Quality and Uniformity of Crop: The preparation of a field intended for tobacco will, to some extent, be controlled by the previous treatment of the soil and, to a great extent, by the crop last on the land. The soil should be broken deep and well--all of the land should be broken, leaving no "balks" or unbroken places. The depth to which the land is plowed should not be less than 8 inches, and, as a rule, 12 inches will be better. If, however, the previous breaking has been less than above indicated, the plowing should be from one to three inches deeper. The breaking should be done a length of time ahead of transplanting so as to give ample time for the soil to settle and to reduce the surface to a well-fined or pulverized condition which is necessary to make the surface smooth and mellow. At intervals the field should be gone over with a harrow to destroy any crust that may be formed and to retain moisture. If this is done less rain will be required to produce good transplanting conditions, the stand will be better and the plants will grow off more promptly and be more uniform in size.

Killing the Pests: If, when the land is first plowed, there is vegetation growing on it there probably will be cut-worms as well as other insects. In such a case the preparation should be far enough in advance of transplanting to destroy such vegetation and starve out these insects; or, poisoned bait should be used. Poisoned bait may be made by dissolving a pound of sugar in five gallons of water and adding five pounds of bran and mixing thoroughly. To this is added an ounce of Paris Green. About a table-spoonful of this is dropped through the field at intervals of about five feet. Another good bait may be made by spraying a small portion of a clover field with an ounce of Paris Green to six gallons of water. The clover is then cut and wads of the poisoned clover are dropped through the field in chunks about five or six feet each way. These baits should be put out

"Your V-C Fertilizers have given me perfect satisfaction, having used same for several years. This year I used for Tobacco 800 pounds of V-C Fertilizers per acre, and have the finest Tobacco I ever saw grown anywhere. I feel it my duty to my fellow farmers to advise the use of V-C Fertilizers for good Crops and as a land builder."

DOC D. HARRELSON, Loris S. C.

Page 14

late in the afternoon. They will last longer and be more effective if they are covered with a board or partly covered with earth to prevent too rapidly drying out.

Fertilizing Tobacco

Of Great Importance: In the production of tobacco of high price, heavy yield and of good quality, commercial Fertilizers exercise a most controlling influence. Should the tobacco growers of any one of the many tobacco sections of the United States be prohibited the use of commercial Fertilizers they would have to go out of the business. Notwithstanding the great effect of Fertilizers upon tobacco, many growers show carelessness or ignorance and poor business judgment when they purchase Fertilizers for this profitable crop. Further, the exercise of expensive false economy in the use of small quantities of

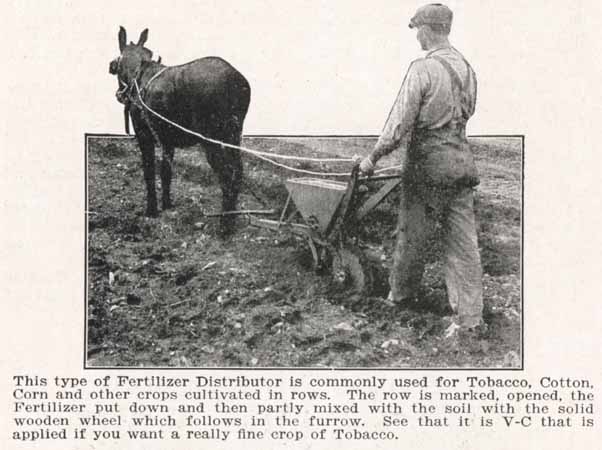

This type of Fertilizer Distributor is commonly used for Tobacco, Cotton, Corn and other crops cultivated in rows. The row is marked, opened, the Fertilizer put down and then partly mixed with the soil with the solid wooden wheel which follows in the furrow. See that it is V-C that is applied if you want a really fine crop of Tobacco.

low grade goods is responsible not only for most poor crops of tobacco but for the wearing out of many thousands of acres of good tobacco land. Realizing that many tobacco growers were annually losing considerable profit which they were entitled to, several of the State Experiment Stations and the National Department of Agriculture have conducted a number of practical tests for the purpose of showing by comparison the great importance and the real value of commercial Fertilizers under tobacco.The Proof of the Pudding: The Texas Experiment Station (Bulletin No. 144) used $20.50 worth of a complete Fertilizer under an acre of sugar leaf tobacco and produced 1,132 pounds, while only 510 pounds were produced on an acre to which no commercial Fertilizer

Page 15

V-C Fertilizers were not used on Tobacco field shown in upper picture. On this 20-acre field in lower view, 640 lbs. of V-C to the acre were applied, producing a yield about 900 lbs. per acre, bringing an average of from $16.00 to $20.00 per 100 lbs. This is part of Mr. J. B. McCormac's field of Tobacco near Danville, Va.

Page 16

was applied. This was an increased yield of 622 pounds due to the effects of the Fertilizer. In another test reported in the same Bulletin, $24.60 worth of Fertilizer gave a yield of 1,245 pounds of tobacco to the acre, and no Fertilizer only 517 pounds, an increased yield of 728 pounds per acre due to the Fertilizer. The same Bulletin reports 1,365 pounds of tobacco from the use of $32.60 worth of Fertilizer and only 430 pounds per acre when no Fertilizer was used, an increase of 935 pounds per acre from the use of commercial Fertilizer. In classifying these several lots of tobacco that were produced through the use of commercial Fertilizers they graded "very good" while the product from the unfertilized acres graded "unfit for commercial use."

Applying 1,000 lbs. of V-C Fertilizers per acre on this 8-acre field of Tobacco, produced 1,200 lbs. of fine Tobacco per acre on the farm of Mr. T. F. DeJarnette, South Boston, Va. No wonder Mr. DeJarnette is an enthusiastic user of V-C.

How It's Done in Tennessee: The Tennessee Experiment Station Bulletin No. 86 sold 887.6 pounds for $108 from an acre fertilized with 750 pounds of commercial Fertilizer and secured only $21.24 for 212.4 pounds grown on an unfertilized acre. The same bulletin reports the sale of $120 worth of tobacco from an acre fertilized with 900 pounds of a complete Fertilizer and only $59 from the product of an unfertilized acre. In still another test 800 pounds of Fertilizer produced a crop which sold for $67.52 while an unfertilized acre produced a crop worth only $31.76.

Virginia Knows How: The Virginia Experiment Station in Bulletin No. 198 reports an acre without Fertilizer applied gave a yield of 820 pounds of tobacco which sold for $49.40 and another acre fertilized with 1,175 pounds of a complete special tobacco Fertilizer gave 1,450 pounds of leaf which sold for $124.54 profit above cost of Fertilizer. The same Experiment Station (Bulletin No. 196) sold from an acre fertilized with 1,500 pounds of a complete Fertilizer 1,185 pounds of leaf at a price which netted $112.10 per acre after deducting the cost of the Fertilizer but grew only 80 pounds on an unfertilized acre

Page 17

which sold for only $4.08. The same Bulletin reports 1,570 pounds of tobacco worth $174.29 from the use of 1,300 pounds of a complete Fertilizer and 805 pounds from an unfertilized acre worth only $61.98.

North Carolina Does the Same: The United States Department of Agriculture conducted tobacco experiments at Greenville, N. C., and at Oxford, N. C., with results showing remarkable effects from the use of commercial Fertilizers. At Greenville 1,264 pounds of complete Fertilizer yielded 905 pounds of tobacco worth $87.36, and another acre with no Fertilizer yielded only 120 pounds of tobacco worth $4.38. At Oxford 800 pounds of complete Fertilizer yielded 760 pounds of tobacco, worth $179.20 and no Fertilizer yielded 140 pounds of tobacco worth $6.40. It would be difficult to imagine evidence stronger than the above actual results, to prove the great profit due to the judicious use of the right kind of Fertilizer for tobacco.

The average Tobacco grower does not use enough Fertilizer to be assured of a maximum crop. Instead of 200 or 300 pounds per acre it will be found that an application of 1,000 to 2,000 pounds per acre will invariably produce the best results. And be sure you use the best, which is V-C.

The Best is the Cheapest: The value of a ton of Fertilizer is controlled by the number of pounds of plant food it contains, and the plant food in a low grade Fertilizer costs the tobacco grower more than the plant food in a high grade Fertilizer reckoned by the pound, by the sack or by the ton. The plant food in a low grade Fertilizer not only costs more than the plant food in a high grade article but it is not so good.

Application and Distribution: The methods of applying Fertilizers for tobacco vary in different sections, the variations depending upon the method of planting and the type of tobacco grown. The Fertilizer may be sown broadcast, distributed continuously in the drill or applied in the hill. When due regard is paid to the permanent improvement of the soil, broadcast applications are often preferable. Applying continuously in the drill is probably the easiest method of application. Applying in the hill is resorted to mainly when the tobacco is planted in checks. Heavy applications made in the drill may cause "firing," and hill applications are even more liable to cause this damage. The distribution of the Fertilizer, by whatever means possible, throughout

Page 18

the soil area to be occupied by the roots of the tobacco plants, will give best yields and best quality.

Abundant Feed, Abundant Yield: The amount of Fertilizer that may be used with the greatest profit depends upon the natural condition of the soil and the value per pound of the tobacco type to be grown. It is safe to say, however, that the average tobacco grown does not use half as much Fertilizer as would be most profitable and often four times the amount commonly used per acre would give in return more than four times the profit from the use of the greater quantity. Tobacco is a heavy feeder and for high yield and high quality must be heavily fertilized. It would require 85 pounds of potash, 67 pounds of nitrogen and 10 pounds of phosphoric acid to replace these fertilizing elements removed in 1,000 pounds of leaf. Heavy yields and high qualities will not be produced by just enough plant food--there must be an abundance.

Use Manure With Caution: Except for the heavy and coarse types of tobacco stable manure should be used sparingly, if at all, directly under the tobacco. It is better by far to use stable manure on the crop preceding tobacco and upon the poorer spots of the field. The office of

Method of hanging Tobacco in Warehouse. You will always hang the finest grown Tobacco whenever V-C Fertilizers have been applied wisely and abundantly.

stable manure is more to improve the physical properties of the soil than to furnish plant food and with tobacco may do more harm than good if not used with caution.More than One Application Advisable: Fertilizers should be put down between ten and twenty days before the plants are to be set. Many growers put all the Fertilizer down at one application but there is an increasing tendency to make more than one application and the tendency is supported by both logic and practice. In the past it has

Page 19

been considered too expensive to make more than one application, but the advent of the combination cultivator and Fertilizer distributor has reduced the cost of later applications to almost nothing.

An Investment Paying the Highest Dividends: The first late application should be made about four or six weeks after transplanting and the last application about two weeks or a month before the first plants are topped. In growing heavy yields of high priced tobacco the investment which pays the highest dividends is the liberal use of appropriate tobacco Fertilizers of high grade. Many tobacco growers continue to use a cheap cotton Fertilizer under tobacco. This is a mistake, for not only is the yield low, but the quality of the tobacco is injured since these cotton Fertilizers contain potash in the form of Kainit or muriate, both of which are most beneficial to cotton but injure the quality of the tobacco leaf. Further, the cotton Fertilizer often contains only a third or a fourth as much potash as should be contained by a tobacco Fertilizer and the nitrogen may also be too low.

Tobacco culture offers a great reward to the grower who is master in his business. The master Tobacco grower has learned to appreciate the necessity and effects of V-C Fertilizers on his Tobacco crops.

Setting the Plants

Great Care Is Essential: Transplanting the young tobacco plants is a task often left to inefficient hands and is not as well done as is necessary for best results. While setting is in progress careful inspections should be made and the laborers encouraged to place the plants at the proper depth and to very firmly press the earth about the roots. After each plant is set loose earth should be drawn about it to check the evaporation of moisture. Every effort should be made to avoid bruising the plants from the time they are drawn from the plant-bed until the transplanting is done. In drawing the plants from the bed select plants four or five inches high, stocky and free from disease. The drawing of the plants from the bed should be most carefully done so as to injure neither root nor top. If the earth is firm plants may, to advantage, be partially lifted by inserting a small stick under them and prizing them out. After the plants are taken up they may be placed in baskets or trays

Page 20

with the roots down and protected by the tops. If not to be set at once they should be kept in the shade and it will keep them fresh if the basket or trays are set in water.

Care of the Beds: The beds, having been previously made, are dragged down level by a board attached to a plow stock or by a light drag. The earth should be free from all clods, loose and mellow. Transplanting is most economically done as soon after a rain as the ground is dry enough to be worked without injuring it. If a rain does not occur when the plants are of the right size watering must be resorted to. Where watering is necessary the plants may first be set and then a hole opened to one side into which a pint of water is poured. Care should be taken to spill no water upon the plant or upon the surface of the ground. After watering the holes into which the water has been poured they should be filled and covered over with loose earth. Another method and one commonly practiced in some tobacco sections is to make a hole with a dipper, hoe handle or something similar. Water is poured into the holes and soon afterwards the plants are set in the same holes. The plants should be set deeper than they stood in the seed-bed, placing the base of the lower leaves below the surface.

Machine Preferable to Hand: Where the area to be set in tobacco is large enough to justify it the plants should be set by a transplanting machine. Such a machine sets them more uniformly than by hand, spaces them as desired and waters them. Several small growers, by co-operation may employ to advantage such a machine.

Gathering a bountiful harvest where V-C Fertilizers have been applied is almost a universal custom throughout the South.

Prompt Replanting Advantageous: Should some of the plants fail to grow, replanting should be done promptly since it is of the greatest advantage to have the crop grow off uniformly and ripen as near as possible all at one time.

Width and Distance to Plant: The width of the rows and the distance between the plants in the row varies with different types of tobacco and varies with a given type with the fertility of the soil and the quantities of Fertilizers used. In the Burley districts the rows may be from 3½ to 4 feet apart and the plants may vary from 18 to 24 inches in the row. In the dark tobacco areas the plants are commonly set in checks or from 3½ to 4 feet each way. The Texas Cuban plants are set 14 to 16 inches apart in three-foot rows while the Big Cuban hybrid is set 12 inches in rows 3 to 3½ feet apart. Is Pennsylvania the cigar-leaf tobacco is set in the Clinton-Lycoming district 18 to 30 inches in rows

Page 21

Tobacco that sold from $17.00 to $20.00 per 100 lbs., on the farm of Mr. J. H. Warren, near Danville, Va. On these 18 acres an average of 656 lbs. of V-C Fertilizers were used per acre, producing an average of from 800 to 1,000 pounds per acre. Of course V-C pays.

3 to 4 feet apart. The Pennsylvania Broadleaf plants are set 24 to 30 in the rows with rows 3 to 3½ feet wide. Cuban tobacco in Florida is set 14 inches in 4 foot rows and Sumatra is often planted as close as 12 inches in still wider rows. The distance between plants in the row and the distance between the rows has a marked effect upon tobacco but the best distance for any section and for the different tobacco types must be determined by the grower through his experience and the experience of others under like environment. The size of the leaf, its thickness, its elasticity, the size of the veins and the curing are all more or less modified by either too great or too little space between the rows or between the plants in the row. Again the height at which the plants are topped has a direct relation to the space given the plants in the field.

Cultivation

How to Produce Best Soil Conditions: The cultivation of tobacco should begin soon after the plants are set. If set by hand and after a rain the tramping of the field will not leave the surface in a desirable condition. If the field is gone over soon after the plants are set and the surface loosened by a cultivator with a number of points, or

Page 22

by a spike tooth harrow, moisture will be conserved and the weeds destroyed. If the plants are not set in checks, so as not to admit of cultivation both ways, the spaces between and around the plants should be loosened with a hoe or rake. Cultivation should be continued at frequent intervals and always as soon after a rain as the soil is dry enough. The objects of cultivation are to prevent the formation of a crust, to loosen the surface so as to admit air and at the same time conserve moisture, and to destroy weeds. If the cultivation is frequent enough and thorough enough to keep the surface well pulverized, practically all weed growth will be incidentally suppressed.

Level Culture the Best: Level culture is best for tobacco as it is best for cotton and corn. If leaf culture is not practiced the implements doing the best work and in the least time, and consequently most cheaply, cannot well be used. The high beds made by some tobacco growers is an evil following poor preparation and following poor fertilization of the soil before the plants are set. If the soil is properly prepared before the plants are set frequent shallow cultivation will give the best soil conditions for prompt, regular, uniform and desirable growth and maturity of the crop.

Eliminating the Weeds: Just what kind of cultivation should be done and the implement that should be used will vary to some extent with the season and the amount of weed growth to be killed. Weeds should not be allowed to grow in a tobacco field. They take up moisture, crowd the tobacco plants and consume the Fertilizer intended for the tobacco crop. Frequent and shallow cultivation done at the right time and with the right implement will kill them before they can attain a sufficient size to do damage and they are killed with the least effort and expense.

Avoid Bruising and Tearing: One of the items of expense in the production of a crop of tobacco is that of the hoe work. This may very materially be reduced by the timely use of the cultivator. Every precaution should be taken to avoid injury to the plants while cultivation is being given the crop. Any bruising or tearing of the leaves will injure both the yield and the quality of tobacco.

Mr. W. A. Erwin, President of the Erwin Cotton Mills Co., of Durham, N. C. knows the great value of V-C Fertilizers as is here evidenced. The excellent field of Tobacco was grown on his farm with the aid of V-C.

Page 23

Topping

The Life of the Plant: The ultimate object in the life of each plant is the production of seed that its kind may be continued. The seeds of plants are the richest in plant food constituents. Just before the seed head of tobacco forms and while it is forming the nutriment intended for the development of the heads is in the leaves. The removal of the seed-producing part of the plant does away with the demand for seed production and the nourishment intended for their development remains in the leaves to improve their quality and add to their weight. When the bud of the tobacco plant has reached a certain stage of development, it is removed. This is called "Topping" and consists in cutting or pinching off of the terminal or flower bud. Topping

No. wonder Mr. J. Rufus Creech, of Pine Level, N. C., is such an enthusiastic user of V-C Fertilizers. He used only $50 worth of V-C on this 5 acre tract which produced a crop of excellent Tobacco which sold for $1,000 without being graded. $50 for cultivation; $50 for V-C Fertilizers--cost $100, profit $900.

is usually done by pinching when the bud is just large enough to be removed without injury to the top leaves. All plants do not develop their buds at the same time and the field must be gone over several times, each time removing the buds that have attained the size for removal.Safe Guides: It is customary to leave from 14 to 18 leaves on Burley tobacco, 10 to 14 on dark tobacco, 12 to 16 on the Pennsylvania Broadleaf varieties, 10 to 15 on the Virginia Sun-cured tobacco, 14 to 16 on the Florida Cuban, all leaves are left on the Florida Sumatra type and, the Bright varieties are topped to from 10 to 18 leaves. Cigar filler varieties are topped low that the leaves may be heavy and thick. Cigar wrapper varieties are topped high that their leaves may be produced. In all types, strong, vigorous plants are topped high in proportion to their strength and vigor, and smooth, weaker plants are topped lower. Topping, like so many of the operations in tobacco culture is controlled by environment and type and only good judgment and experience are safe guides, and these must be coupled with knowledge of the requirements of the tobacco grown and variations in soil conditions. Topping should not be done when the plants are wet with dew.

Page 24

Suckering

How and When to Do It: When the effort of a tobacco plant to make seed has been thwarted by topping, it soon starts other buds in the axils of the leaves. These buds are called "suckers" and are removed to prevent their consuming nutriment which should go into the leaves. The first suckers appear soon after the plants are topped and these should be removed when they are about three inches long, or as soon as they are large enough to be easily removed and removed without damaging the leaves. The longer they remain on the plant the greater the harm done by them. In warm, moist weather it is often

Here's a wonderful picture of 60,000 hills of excellent Tobacco on the farm of Mr. P. H. Thomas, Danville, Va. This is an every-year occurance with Mr. Thomas for he has now used V-C Fertilizers for over 16 years. He annually profits by it.

necessary to sucker the field two or even three times per week. The suckers not only interfere with the development of the leaves but rob them of moisture and plant food, injuring the quality of the crop. Suckering should not be done when the plants are wet.

The Seed Plants

Great Care Essential: There is no American field crop with which so great care is taken in the production of seed as is taken with tobacco. The uniformity of the individual plants in a tobacco field control to a great extent the amount of money the crop will command. The uniformity of a type is due to the fact that all the plants of a given field come from seeds of a very few seed plants, and to the leaving of only the best plants for the productions of seed. Each tobacco grower should allow several plants more than he needs for seed to develop that the best from these may be selected. Each seed plant should approach as near as possible the ideal plant of its type. It is not necessarily the largest plant that is best. It may be coarse, since extra size is often associated with coarseness. Coarse veins should be carefully avoided.

Page 25

The leaves should be close together on the stem and of a shape and size appropriate to the type of tobacco represented by the seed plant.

When and How to Make Selection: The selection of the seed plant should be made before the bud or button is large enough to be removed. The bud is of course allowed to remain, but otherwise the plant is treated as are the others in the field. The same number of leaves should be left on the seed stalks as are left on the crop stalks and all suckers, if any, should be removed promptly. Before the blossoms open the seed head should be covered with a manila paper bag, that all possibility of cross pollination may be avoided. If some of the blossoms have opened before the bags are put on these should be clipped off, since insects may have brought pollen from elsewhere. In a week or ten days after bagging, the seed heads should be examined and superfluous parts of the head removed. In about three weeks the bags may be taken off permanently and all buds which have not opened by that time should be removed.

How to Get Best Results: When the pods have become brown the seed head may be cut and hung in a well ventilated dry place until the pods are perfectly cured and dry. The seed brown, self-fertilized plants are far superior to those indiscriminately fertilized by pollen from several stalks and the careful tobacco grower will find it to his advantage to keep the seed from each plant separate, plant them in different parts of the same plant-bed, or each lot in a bed to itself, and tranplant to different parts of the field. This will give greater uniformity in ripening and in grade, and the different lots, if put on the market separately, will bring a better price.

Here's the "proof of the pudding." These four Tobacco plants were planted at the same time--the two on the left not fertilized; the two on the right were fed with V-C Fertilizers.

Page 26

TO V-C OR NOT V-C AND HERE IS THE ANSWER

Upper left view is on farm of Mr. J. W. Blankenship, near Danville, Va., who used on this 20-acre tract 650 lbs of V-C to the acre, producing 800 to 1,000 lbs. per acre, averaging $17.00 to $20.00 per 1000 lbs.

Lower left corner view is on farm of Mr. J. H. Warren, also near Danville, Va. This 20-acre patch averaged 800 to 1,000 lbs. per acre on which 665 lbs. of V-C Fertilizers were applied.

On two center fields in above group V-C Fertilizers were not used. Compare these two Tobacco fields with those adjoining, on each of which V-C Fertilizers were bountifully and wisely applied.

Upper right corner had 660 lbs. of V-C per acre, producing 900 lbs. per acre. Owing to high quality of Tobacco the highest price was obtained by Mr. M. G. Bryant, near Danville, Va.

Lower right corner view is a section of 25-acre Tobacco field of Mr. Lee Brown, who used 3,000 lbs. V-C Fertilizers per acre, giving a yield of 1,800 lbs. per acre, bringing an average of $17.00 to $20.00 per 100.

Page 28

How to Get Rid of the Chaff: When the seed is threshed from the seed pods the light and chaffy seeds should be gotten rid of. This may be partly done by letting them fall upon a sheet while a gentle wind is blowing, but the best plan is to grade them by the use of a separator or seed grader devised by the Bureau of Plant Industry, Washington, D. C. This apparatus separates the chaff and light seeds from the heavy ones and enables the tobacco grower to plant only the best seeds.

Importance of Leaf Texture: When the top and suckers of a tobacco plant have been removed, the food materials prepared in the leaves for the growing parts of the plant and for the development of the seeds remain in the leaves, and very soon after the removal of these parts the plants enter upon the ripening process. If the type of tobacco grown should have a heavy and dense leaf, fewer leaves are

An enthusiastic Tobacco grower is Mr. John W. Lambert, of Germantown, N. C., who has learned to appreciate the ample and wise use of V-C Fertilizers, as this view of his Tobacco crop proves.

left on the plant so that the food supply may be concentrated in them and give the desired heaviness and density. If a light, thin leaved type is being grown a greater number of leaves are left on the plant and topping is delayed. This prevents the concentration of the plant food and the leaf is thin, more pliable and in other ways differs from the more dense ones.Proper Degree of Maturity: Different degrees of ripeness mark the best period for harvesting different types of tobacco and even the same type under variable soil and climatic conditions. The different types of tobacco should be harvested when each has reached that degree of maturity at which, when harvested, it is susceptible of being cured into leaf of the best grade for that type. The grower should have knowledge of the proper degree of maturity at which the type of tobacco he is growing should be harvested. Ripening is indicated by a change in the color of the leaves. They become a lighter green and later turn yellow and darker spots appear. The lower leaves ripen first and then successively on to the top. Some harvest when the middle

Page 29

leaves are just right so as to get an average maturity. This, plan, however, has the objection that the lower leaves are over ripe and the top leaves are not ripe enough. In some sections the leaves are removed as they ripen and are strung upon laths or "tobacco sticks."

Harvesting Cigar Tobacco

Best Stage of Ripening: In fifteen or twenty days after topping the leaves begin to change color, light greenish spots appear and the leaf snaps when sharply folded between the fingers, indicating ripening. Experience and good judgment are necessary to determine when the best stage of ripening has been reached and the success of curing and the quality of the cured leaf depends largely upon harvesting at the proper time. In the northern districts harvesting begins about the middle of August and may extend into October. The weather condition or season may cause a variation of ten to twenty days in the time of ripening. When cut, the plants are arranged uniformly along the row and allowed to wilt so that the plants may be handled without breaking the leaves. No cutting should be done while the plants are wet and all plants should be removed from the field the day they are cut. Every care should be taken to avoid sunburn. The plants are strung on laths in the field and hauled directly to the curing shed, though some still follow the old plan of partly curing on scaffolds. A specially constructed wagon frame is used for hauling the lathed stalks to the sheds. The greatest care should be taken in the spacing of the laths on the poles of the curing shed--hanging them 6 or 7 inches apart on the upper and 8 or 10 inches on the lower tiers. Close hanging will give better curing in dry weather but more space should be given in wet weather. However, until it may be known beforehand with certainty what the weather will be, a middle space must be adopted. Several days after the barn has been filled thorough ventilation should be given, and it will often be of advantage to scatter some lime over the floor.

Mr. H. H. Rose, of La Crosse, Va., is proud of this fine patch of Tobacco which yielded about 2,000 pounds to the acre. Every leaf seems perfect. 800 pounds of V-C High Grade Fertilizers per acre helped to produce this gratifying result.

Page 30

Harvesting Cigar-Wrapper Leaf Grown in Shade

An Important Industry: The growing of wrapper tobacco in artificial shades has developed into an important industry in parts of Florida, Georgia, and Connecticut, and requires some differences in handling. That the highest yield of the best quality of wrapper may be secured, the leaves are stripped from the stalks as it stands in the field. This type of tobacco is harvested before it has reached the degree of ripeness necessary to other types, nor does it so plainly develop the conditions indicating ripening. The first harvest removes the lower three or four leaves which are placed in baskets and hauled at once to the curing shed. The field is gone over three or four times before the harvest is ended so that the leaves may be taken when at the best stage of ripeness.

Method of Stringing: In the Southern districts the leaves are strung on twine fastened to each end of laths. Some 30 or 40 are strung on each lath by means of the twine, a needle being used for the purpose. In stringing the leaves they are placed in pairs, every alternate leaf facing in the opposite direction to prevent them sticking together. In the Northern district another method of stringing is used. Wire nails are driven through the laths at intervals of about two inches, giving 40 nails to the lath, or 20 to each side. One leaf is hung on each nail, the leaf facing outward from the lath.

This is the kind of Tobacco 700 pounds per acre of V-C Fertilizers helped to grow on Mr. W. M. McAden's farm at Diamond Grove, Va. It pays to use V-C.

Harvesting Burley Tobacco

Two Methods: When the plants are well ripened the stalk is split with a knife down to about one-third of its length from the ground and cut off. The split plants are then placed astride tobacco sticks, which usually are 4 1/3 feet long and hold about six plants. These sticks are hauled to the barn on specially constructed wagon frames and hung about a foot apart. Some growers continue the practice of scaffolding for from two to four days before placing in the barn. When allowed to wilt on scaffolds the stalks may later be placed closer together in the barn.

Page 31

Harvesting Sun-Cured Tobacco

Modified Air-Curing Process: In portions of Virginia a plug filler tobacco is grown which has characteristic properties produced by the special process of curing. The curing is a modified air-curing process. The stalks are harvested as they ripen and are scaffolded in the field

Field in upper view produced about 100 lbs. to the acre, field in lower view produced an average of 1,000 lbs. to the acre. V-C Fertilizers were applied on field shown in lower view, whereas V-C Fertilizers were not applied on fields shown in upper view. Lower view is on field of Mr. J. W. Blankenship's farm, near Danville, Va.

Page 32

whether the tobacco is exposed to the sun until nearly cured. It is then removed to the barn and there remains until ready to be stripped. If cloudy weather follows the harvesting of this type of tobacco it gets but little sun, if any, and its manner of curing then becomes about the same as that of the Burely and some of the cigar types.

Harvesting Yellow Tobacco

Two Methods: The greater portion of Yellow Tobacco which is grown in North Carolina, Virginia, South Carolina and Tennessee, is harvested in two ways: by cutting the whole plant or by removing the leaves as they ripen. It naturally follows that cutting the stalk when the middle leaves have reached the best degree of maturity will find the top leaves too green and the bottom leaves over ripe; and that removing the leaves as they are just right for harvest will give more uniform degree of ripeness, better quality and naturally a higher price will be paid. As to which method should be followed there is a difference of opinion among growers. If the stripped leaves bring the greatest net profits this method should be followed, and vice versa. It has been found that the stripped leaves are heavier than those left on the stalk, since those left on the stalk lose some of their sap by the sap going back into the stalk while the leaf cures. Some growers maintain that the best plug wrappers can only come from curing the leaves on the stalk.

Good Color Desirable: Yellow tobacco is allowed to become riper than other types. The whole plant should appear yellowish green and leaves have spots of lighter tint and with a deeper yellow than the remainder of the leaf. Good color is desirable in yellow tobacco, and to secure this, experience and good judgment is required in determining the best time to harvest.

Handling the Stalks: When the whole plant is harvested the stalk is split from the top to near the bottom and cut near the ground. The stalks are then placed astride sticks, 6 to 9 to the stick, and the sticks

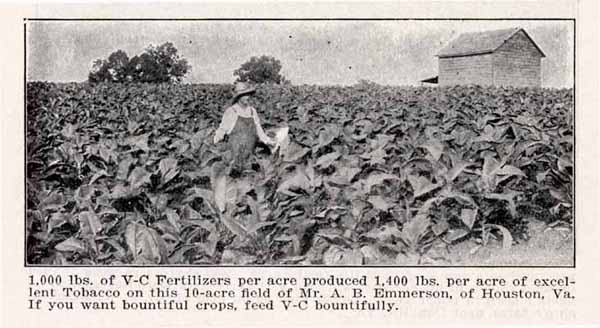

1,000 lbs. of V-C Fertilizers per acre produced 1,400 lbs. per acre of excellent Tobacco on this 10-acre field of Mr. A. B. Emmerson, of Houston, Va. If you want bountiful crops, feed V-C bountifully.

Page 33

loaded upon wagon frames constructed for the purpose and taken to the barn where they are hung upon tier poles, the sticks being placed from 8 to 12 inches apart.

Removing the Leaves: When harvested by removing the leaves from the stalk, three or four leaves are taken the first round and as the remaining leaves ripen they are removed in like manner until all are harvested. This requires that the stripping of the ripe leaves be done three or four times. The leaves are placed in baskets and hauled to an arbor or directly to the barn. They are then hung on sticks, which are usually 4 feet 4 inches long, by the use of cords or wires.

On this 20-acre field of Tobacco on farm of Mr. T. A. Cage, South Boston, Va., 1,000 lbs. of V-C Fertilizers were used to the acre, producing 1,400 lbs. of fine Tobacco to the acre. There are quite a few progressive Tobacco growers in South Boston, who have learned to know the great value of V-C in producing fine and bumper crops of Tobacco.

The Harvesting of Export Tobacco

A Later Maturing Type: This is later than other types since it matures later. Its later maturity is largely due to the fact that it is usually grown on a different type of soil and one which induces later maturing. If allowed to stand sometime after topping it gains considerably in weight of leaf. When ready for harvest the leaves droop, becoming thickened and heavy and snap when folded between the fingers. Two and sometimes three cuttings are made, since the plants are not all ready for the harvest at one time. The stalk is split, cut off near the ground and placed on sticks 4 feet and 4 inches long and hauled to the barn. Six to 10 plants are on each stick. When hung in the barn the sticks are placed 8 to 10 inches apart. Some scaffold their tobacco in the field before taking it to the barn. If scaffolded, every precaution must be taken to avoid damage from rain.

Page 34

Harvesting Perique Tobacco

Different Methods: This type is grown almost exclusively in St. James Parish, Louisiana; differs from the methods of harvesting other tobacco. The peculiar soil and climatic conditions of this region induces a quick growth and early maturity. Harvesting begins in early summer and the plants are cut in the middle of the day, carried to the curing house and hung by ropes attached to shivers of cane driven into the base of the stalk so as to form a hook to hold the rope.

Curing

Specific Methods for Different Types: Tobacco growing is highly specialized and requires expert attention to attain best success. The curing of the different types is markedly differentiated, requiring special care, experience and knowledge of specific methods appropriate for the different types, though some types require much simpler processes than others. To produce the best leaf and to command the highest price the curing of each type must be carried through in its peculiar way that the physical and chemical changes incident to curing may be brought about and that the cured product may possess the qualities sought in each type. The curing of tobacco is more than the simple drying of the leaf, it involves changes in the leaf which are brought about by the method of curing. These changes must be governed so as to develop the qualities which the different types of tobacco are expected to possess.

Another fine Tobacco crop on the farm of Mr. Hitchcock, Fair Oaks, Va. Fine, high-priced, free-burning Tobacco always follows the wise use of V-C Fertilizers.

Conforming to Trade Requirements: To do this the curing must be so conducted as to suit the requirements of the class or type of tobacco being cured and the qualities it must possess that it may conform to the trade requirements. It is necessary to the highest degree of success that the grower be well acquainted with the trade requirements and thoroughly familiar with the condition necessary for curing into a product possessing the best qualities of the type he is producing. Long experience and the exercise of good judgment are necessary to the production of the best qualities in the various types and classes

Page 35

of tobacco. Since these variations in the manner of curing the different types are in many cases essential to the curing qualities desired in each type, it is proper that the different types be considered separately.

Curing Cigar Tobacco

Atmospheric Conditions of Great Importance: If the weather conditions are favorable no artificial heat is used for curing cigar tobacco. If danger of pole-sweat occurs charcoal fires are made. The humidity of the air in the barn, as well as the temperature, is rarely under control save that afforded by ventilation. The leaf should be cured rapidly enough to avoid injury from pole-sweat, but if the curing is too rapid the leaf will become dry before the changes in the leaf which give the desired quality have taken place. If the outside air is very dry the barn should be kept closed both day and night. If the outside air is very wet the barn should be kept open through the day. If the outside air is neither dry nor wet the lower ventilation only should be opened. When the leaf becomes yellow the humidity of the barn should be lowered that the desired brown color may be developed. This is the critical stage in curing cigar tobacco. If a dark leaf is desired the humidity of the air in the barn should be relatively high as compared with the humidity necessary to the development of bright leaf. The first stages of curing this type of tobacco should be accompanied by the presence of high air humidity, and as soon as the desired color is obtained dry out the leaf more rapidly. The curing is completed when the mid rib is dry enough to break when bent between the fingers. The stalks should be green when the tobacco is ready to be taken down.

350 TONS OF V-C IS GOOD PROOF OF SATISFACTION

"We congratulate you on your efforts in getting up this Fertilizer. We have today furnished your company with an order for 300 tons of V-C for shade-grown purposes and 50 tons for plant-bed purposes, and have requested your company to prepare the shade-grown Fertilizers by same formula in every respect as that used the past season."

AMERICAN CIGAR COMPANY, New York, N. Y.

Page 36

Shade-Grown Wrapper Leaf

More Rapid Curing Process: This tobacco is cured after stripping the leaves from the stalk and consequently cure in less time than leaves left on the stalk. The temperature and humidity are more easily controlled also. In the earlier stages the curing must be rapid enough to avoid injury from too much moisture but it must not dry too fast. If windy weather occurs the ventilation must be partly closed to prevent damage to the leaves by high wind. As soon as the desired brown color develops the curing may proceed more rapidly. The stem dries out more slowly than the leaf proper and from 4 to 6 weeks are necessary to the completion of the curing process. After the leaves have been cured they are allowed to remain in the barn until they cure sufficiently to be handled; then they are tied into bundles.

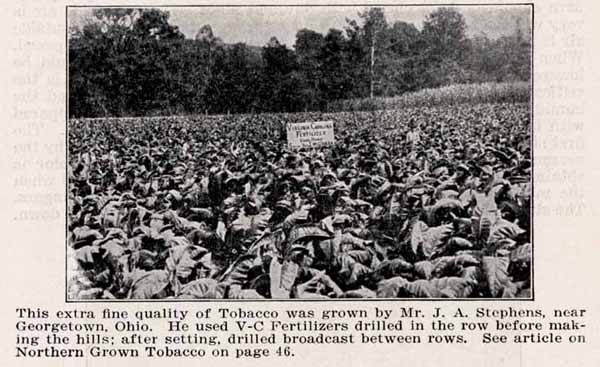

This extra fine quality of Tobacco was grown by Mr. J. A. Stephens, near Georgetown, Ohio. He used V-C Fertilizers drilled in the row before making the hills; after setting, drilled broadcast between rows. See article on Northern Grown Tobacco on page 46.

Burley Tobacco

Practically Same Method as Cigar Type: This is cured practically by the same method as that employed for cigar tobacco, though the color is yellow or reddish when cured and not brown. If dry weather occurs while curing is going on the barn should be kept closed by day and open by night. If the weather is wet the best of ventilation must be given. In damp weather it is often necessary to employ charcoal fires to avoid pole-sweat. The curing process lasts from five to seven weeks.

Curing Sun-Cured Tobacco

A Sun Depended Type: This is affected mainly by the air-curing process and sunshine is depended upon for the development to the properties and characteristics of this type of tobacco. If the weather is

Page 37

cloudy to any considerable extent while the curing is in process the desired properties are not fully attained. The tobacco is scaffolded in the field with exposure to the sun until nearly cured when it is taken to the barn to hang until ready for stripping.

Curing Yellow Tobacco

Several Important Factors Essential: This is done by a process through which the temperature and humidity of the barn is under control and varied so as to secure the characteristics of this type. Several specific formulas for curing yellow tobacco have been employed with success, but any formula used must be modified to meet varying conditions that may accompany each lot of tobacco cured. Each of these formulas is based primarily upon temperature, while there are other factors of equal importance that must be closely watched. The tobacco should be subjected to close observation as to temperature and by one who has had sufficient experience in curing yellow tobacco to know what the condition of this tobacco should be at each period in the curing process. The thermometer is hung near the center of the barn in the lower tier of tobacco so that it may be readily examined. The barn should be completely filled in one day, and as soon as filled small fires are started in the furnaces and maintained at a comparatively low temperature until the leaves have become thoroughly yellowed. During this period the barn is tightly closed from 24 to 36 hours. The temperature is started at about 80 degrees F. and gradually raised to 110

On this lot of shade-grown Tobacco, Mr. J. L. Glauson, of the Ware Orchard Co., used V-C Fertilizers. As manager for the Ware Co., at Americus, Ga., Mr. Glauson is in a position to know the value of these High Grade Fertilizers.

Page 38

or even 120 degrees F. These 24 to 36 hours complete the yellowing process and following is the critical part of curing, known as fixing the color.

Fixing the Color: This is affected by the rapid removal of moisture from the leaf and as rapidly from the barn as it is given off by the leaf. To accomplish this ample ventilation is necessary and the tobacco must be closely watched night and day. If moisture collects on the leaf more ventilation must be given at once. At no time in the period should the temperature be allowed to fall, but gradually raised until 135 degrees F. is reached. If the temperature is not high enough and if ventilation is not good the leaf will turn reddish or "sponge." If the temperature is too rapidly raised while the leaf is full of water the leaf will "scald" or "blister" by turning a greenish black. A moderate temperature carefully regulated and ample ventilation are necessary to the avoidance of these troubles. After completing the yellowing process, the temperature is maintained at about 135 degrees F. until the leaf has dried. This takes from 10 to 18 hours and at the completion of this period there is no further danger of scalding.

Drying Out Stems: The next step is the drying out of the stems by closing all ventilators and raising the temperature to 160 or 170 degrees F. by stages of five degrees per hour. The high temperature is maintained until all stems are well dried. Some growers carry the temperature as high as 200 degrees F. but this is dangerous and may result in the loss of the barn and its contents by fire. The dying out of the stalks completes the curing.

Curing Export Tobacco

Here Haste Makes Waste: In curing this type of tobacco care must be taken not to dry out the leaf before the desired colors have been obtained and other changes have taken place. No heat is used for the first three or four days. On the fourth or fifth day slow fires are started on the floor of the barn and for 22 to 26 hours a temperature between 90 and 95 degrees F. is maintained that the yellowing of the leaf may develop at this low temperature. As soon as the yellowing process is completed the temperature is raised to 125 or 130 degrees F. by slow degrees and held there until the leaf is well dried.

"The proof of the pudding." There is always proof of the results produced by using V-C Fertilizers. See last page.

The fires are thus allowed to die down and the flow of sap into the leaf makes the leaf soft and pliable again. The fires are again built and the process repeated for several weeks allowing the leaf to alternately dry out and soften until both stem and leaf are completely cured.Avoid Too Much Heat: In the early stages of firing when the tobacco is green, heavy and sappy, too much heat may cause "scalding" and a careful watch must be kept on the condition of

Page 39

the tobacco. If it is necessary that the tobacco hang in the barn any length of time after curing, slow fires should be maintained in periods of wet weather to prevent the development of mold and to avoid too dark a color in the leaf.

Curing Perique Tobacco

Where No Heat Is Necessary: This unique type of tobacco is cured without artificial heat and the leaves are stripped from the stalk as soon as they become brownish, three or four being taken at a time. The leafy part of the leaves are stripped from the stems while they are yet green and made into rolls. These rolls are packed into boxes which hold about 50 pounds each. While in the boxes the tobacco is subjected to a pressure of several thousand pounds for twenty-four

Not alone a fine growth of Tobacco but a high quality is the result of using V-C Fertilizers wisely on the 15-acre farm of Williams & Newman, Brown Co., Ohio. See article on Northern Grown Tobacco on page 46.

hours. The tobacco is then taken from the box, the rolls opened and exposed to the air. The tobacco is again rolled and subjected to the heavy pressure, opened and dried and this repeated every 24 hours for ten days. After this the process is repeated at intervals of several weeks until the leaf is well cured or when its color has become black.

Handling Cured Tobacco

A process of Handling Which Requires Care: Stripping and sorting Cigar tobacco should begin as soon after it is cured as it is in good enough condition to be handled without damage. The plants are taken from the laths and placed in heaps, tips in and overcapping to prevent drying. Stripping should not be delayed or the piles may heat. The top leaves are first removed and piled as fillers. The next three or four are simply removed and piled as seconds. Finally the best leaves are classed as wrappers and the grades tied into "hands" bound together with a leaf. Each "hand" should contain leaves of the same quality of uniform length and weigh about half a pound. The "hands" are then bulked in double rows with the butts turned outward and the tips inward and overlapping, the whole bulk covered with a cloth to prevent drying. A close watch should be kept to prevent heating while the "hands" are bulked down. Should heating begin the piles must be

Page 40